CALCULATION OF POWER FACTOR CORRECTION CAPACITORS

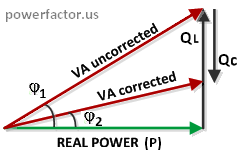

If you can't get QL information from the manufacturer, you can ask an electrician to measure idle current by using a clamp-on meter and multiply the result by the voltage. Technically, this will be total VA, but in absence of working power this result will be close to VAR. Once you determined "QL", the required rating of PFC capacitors will be simply Qc=QL×PFdesired, where PF is given as a decimal. If you are unable to determine no-load VAR, things get a bit more complicated. Let's recall from geometry that the tangent of an angle in a right triangle is the ratio of the opposite side to the adjacent side. Then, as we can see from power triangle diagram, uncorrected and corrected values of reactive power are given by the following equations:

Quncorrected=P×tanφ1

Quncorrected=P×tanφ1Qcorrected=P×tanφ2,

where P- real power. From this we find the required Qc:

Qc= Quncorrected-Qcorrected=P×(tanφ1- tanφ2)

We have three unknown values here: P, φ1 and φ2. Working power P can be measured by a wattmeter. To find φ1 we need to know hypotenuse, which represents apparent power S(VA). So, you need to measure total current under full load and multiply it by the voltage. When we know P and S, assuming undistorted sinewave current without harmonics, we can find φ1=arccos(P/S). Similarly, the desired angle φ2 equals to φ2=arccos(PF2), where PF2 is targeted power factor.

P(kW)=HP×0.746/η, where η is efficiency in decimal (typically 0.8 to 0.95). Substituting φ1 and φ2 into our expression for Qc we get:

Qc(kVAR)=P(kW)×[tan(arccos(PF1))- tan(arccos(PF2))],

where PF1 and PF2 are initial and improved PF respectively (if you have PF expressed in percentage, you need to divide it by 100). Our calculator just implements the above formula. Once you found required kVAR, select a standard capacitor with equal or smaller value. It is always better to under correct than over correct. Note that although normally capacitance is measured in microfarads, to simplify the sizing of PFC caps, manufacturers rate them in kilovars (kVAR). Since Ic=V/Xc and Xc=1/(2πFC), then V×I=2πFCV2, where "C" is in farad, "F" is in hertz. If we express V×I in kVAR and "C" in μF, then the relationship between these two quantities is: kVAR=2πFCμFV2×10-9.

Our widget is for preliminary ballpark estimation only-- read our complete disclaimer linked below. You need an engineer to do a study, suggest a solution and determine if the project makes financial sense.